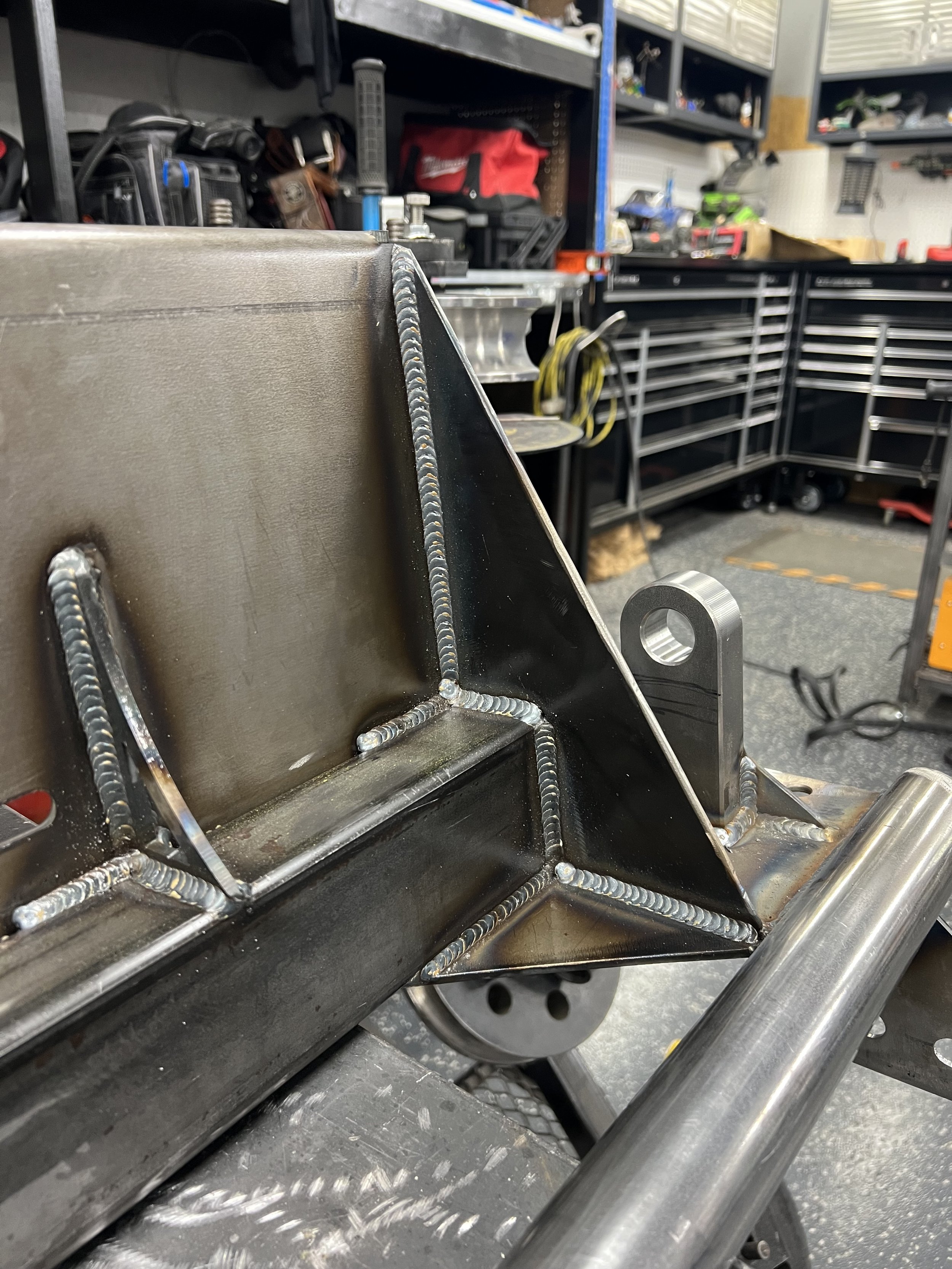

Custom Work

Please understand that I do not ship the majority of what you see me make. Anything that I offer shipping on can be found in the “store” here on the website. I offer DIY sliders for most any Toyota make/model, but I haven’t made it to getting them all listed on here yet. So if that interest you please ask. We are slowly trying to add larger products like bumpers to our shipping list, but it is a slow process.

If you are wanting to get custom work done, you will need to leave your vehicle with me for the entire build. I am located in Tamassee SC. Bumpers and sliders take approx. 1 week build time with swing-out bumpers taking approx. 2 weeks. My availability can be found here on the site under the “build and price” tab. There will be calendar you can reference there. Please keep in mind this calendar may not be 100% accurate. We like to mark time blocks of time off with no jobs in case anything goes wrong with other jobs we do not get behind. So as long as we stay on track those spots become available. We also can work a lot of jobs in. So if serious, please reach out if you have any questions about the calendar. Booking an appointment will require a NON-REFUNDABLE $100 deposit. The rest will be paid once your build is complete.

Pricing for custom jobs can be found here on the site under the “build & price” tab. Please understand that once you complete the form and it prompts you to send an email, that it does not send any of the info you filled out. This form is more for you, so that you can have a ballpark figure on price. If you would like to move forward you can email me and we can go over the details, or message on Facebook or Instagram. (Facebook is my preferred method of contact).

If you are wondering, “ have I built anything for _______ vehicle” or “what have I made or what can I do for ______ vehicle” I can build for anything you can imagine! Sometimes unibodies vehicles are a different story, but we can discuss that. While we are starting to dabble with plate designs, at this time I am only offering full tube or hybrid bumpers, no full plate designs yet. Hybrid designs are typically going to yield around $150 upcharge. Everything I have ever built is on Facebook and Instagram. That is my portfolio, where you can go to see photos of my work and everything I have ever done.

I offer more than just bumpers and sliders. I can do furniture, repairs, handrails, industrial, roll cages, SAS etc. This stuff does not have flat rate prices however so we will need to discuss the build together to work up that price.

NEW! Traditionally when I first started this I was only doing one-off custom bumpers, so for example every 4Runner I did would get a different design. I have started to drift from that, and on the more popular models I am starting to make my own “JC Customs” designs. Once those are completely dialed, I will add them to the “store” in my website. They still will not be able to ship, but they will be a set price and you can browse everything I offer straight from the website . They are going to be more of a “what you see, is what you get” type bumper. Which will mean little, to no customizations. These will be priced a couple hundred dollars under my custom build prices.

Common FAQ

Tubing Bender: The tubing bender I use is a JD2 model 3. Originally it had been converted to air over hydraulic using an 8 ton ram from Harbor freight, and a mount made by Swag Off-Road. It is now converted to electric over hydraulic with parts sourced from Amazon. You can find all that info in a video on my YouTube channel. As well as putting all the links in my amazon store. There is also a video up of the current air/hydro version on my YouTube channel if you would like to check that out.

Material: 90% of what I do is predominantly built with 1.75x.120 ERW or DOM tubing. But you will find 1.5”, 1.25” and 1” tube incorporated into my designs.

Weld Settings: I use a Millermatic 252. I use a lower case e pattern on all materials. I don’t always weld the same material on the same settings. It just depends on the day and how the metal is welding. Here are some baseline settings I use that will get you in the ball park and you can tweak as needed.

1/8 fillet: 16.5/165- 16.9/175

1/8 open corner: 15.5/150-16/155

3/16 fillet: 17/200-17.5/230

3/16 open corner: 16.5/150

1/4 fillet: 18/200-18.5/250

1/4 open corner: 16.5/150-16.7/155

Swing Out Parts: 4xinnovations has a very nice double shear spindle kit. This is all I use for my spindles. Everything else I use can be found on my website. The spare tire triangles, HDPE landing pads and rubber grip latches, etc.

Software Design: I often get asked, “what software am I using for my designs?” The answer is, I am not. I personally believe a lot of software’s really limit your creativity. I really never even have a design thought out, I just start putting tubes where they look good. There is a lot of artistry involved in this stuff and a software is not going to be the fix-all. Use your imagination, draw inspirations from others, but DONT COPY IT! Put your own spin on things. Make it unique! There is nothing worse than someone ripping off others hard work and designs and claiming as their own.

The above statement is regarding tube work. For 2D drawing for my plasma table, I use ProdgeCAD, which is a Wal-Mart version of Auto-CAD. It does everything I need with a price tag of $400 for a lifetime.

NEWBIE/BUISNESS ADVICE: I often get asked or told, “how do I do what you do?” or “I want to start my own fab business, any advice?” Here’s my advice, and this applies to any business, not just fab. If you don’t have a passion for it, don’t do it. Running a business will consume your life. You don’t get to clock out and forget about it at 5:00. You must be prepared to put in the work for very little return in the beginning. You are not going to get rich from building custom bumpers. If you’re in it for the money, look into production based bumpers. These will net a much larger profit margin. My advice will always be to do it on the side, do it for a few years. Really make sure its going to work and you will like it before leaving a good job.

If you’re just looking to get into it as a hobby but have no real idea where to begin, what to buy? I will list off what I would consider the bare necessities for hobby use fab work.

Welder: One of my favorite beginner welders is going to be the Hobart 210MVP. Hobart welders have a very similar weld to Miller welders in my opinion. They weld great, and on the MVP you have the option to switch between 110V to 220V which may very useful for someone who doesn’t have a shop with 220V yet, but plans to later on. My next best option for a beginner welder is going to be the PrimeWeld MIG180. Extremely affordable and comes with a spool gun! Not to mention PrimeWeld has the best warranty in the industry.

Bender: You already know the bender I use and recommend. Lots of guy cheap out here. Rogue Fab is a very popular bender. I personally hate it, but that’s an opinion. I recommend staying with JD2 or either one of their copy cats like JMR or Pro-Tools.

Basic power tools: You do not need a bunch of expensive tools to do metal work. Does it help? Sure, but not needed. A minimum of 2 angle grinders. One for flap disc, and one for cut off wheels. I personally like Dewalt paddle switch grinders for flap disc, and the Milwaukee long neck grinders for cut off wheels. I run about 8 different grinders but 2 will go a long ways. You do not need a fancy notcher, I still barely use one. I prefer to use a portable band saw. Others use an angle grinder or chop saw will the same results. A portable band saw is my number 1 favorite tool. I own 4. Having ran Milwaukee’s for years, I have been trialing the Harbor Freight Bauer saw for over a year now and its fantastic. (It is a direct copy cat of the previous generation of Milwaukee’s, with a few improvements) A chop saw of some sort is also a great tool to have for making consistent straight cuts. You can use an abrasive type or cold cut saw like Evolution sells. I have both and still run an abrasive saw daily. An orbital or DA sander is also a good tool to have, for blending out end caps and what not.

Basic hand tools. Squares, levels and angle finders. Lots of them! A 12”, 24” and 48” level are a must. There are lots of different style angle finders. You will need at least one protractor stile and one dial indicator style. You will find that there are lots of these and different styles. I recommend buying multiple styles to see what you like the most. They all have their place. Get yourself a framing square and speed square. Very useful. If working with a lot of “square” shaped stuff get a set of good squares, like sold at Fireball tools or Genuine Metalworks.